Our Equipment

Precision Starts with the Right Tools.

Our shop is equipped with a wide range of CNC and manual machines to handle projects of various sizes and complexities.

HAAS SL-30 CNC Lathe Machine with Tailstock

Turning table size X-axis 18″ Z-axis 30″

Handles larger diameter parts with excellent rigidity and power.

HAAS SL-20 Big Bore CNC Lathe with Tailstock

Turning table size X-axis 13″ Z-axis 20″

Ideal for smaller, high-precision turned components.

HAAS VF-4 CNC Vertical 4-axis Milling Machine

Table size X-axis 50″ Y-axis 20″ Z-axis 25″

Ideal for precision machining of medium to large parts. Delivers excellent repeatability and surface finish.

Haas VF-5/XT Vertical Machining Center (Extended Travel)

Table size X-axis 63″ Y-axis 26″ Z-axis 30″

Extended table for larger components. Perfect for multi-operation setups and complex geometries.

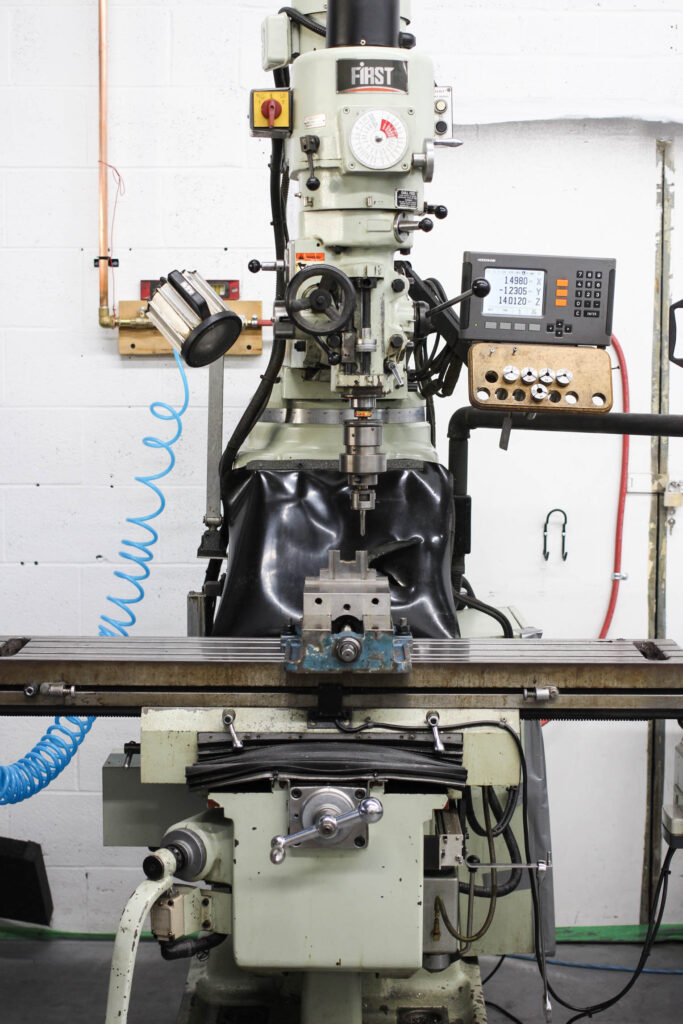

Manual Machines

- Manual Milling Machine – For prototype work, one-off parts, and secondary operations.

- Manual Turning Machine – Used for quick setups and small-batch production runs.

Grinding Equipment

- Automatic Surface Grinder Movement: 10″ × 20″ – Ensures smooth finishes and tight flatness tolerances.

- Manual Surface Grinder Movement: 6″ × 18″ – For precision finishing of smaller components.

Cutting Equipment

- Doall C-916 Horizontal Automatic Band Saw – Efficient and precise cutting of bar stock and billets.

- Vertical Band Saw – Versatile cutting for plates, shapes, and tool prep.

Ready for Your Next Project?

Let’s discuss your next custom machining job! Send your drawings, material specs, and quantity requirements to info@shprecision.ca and our team will review it and provide a detailed quotation.